MINOR CHANGES BETWEEN MILLIMETERS CAN ALSO BE EASILY EXPLORED.

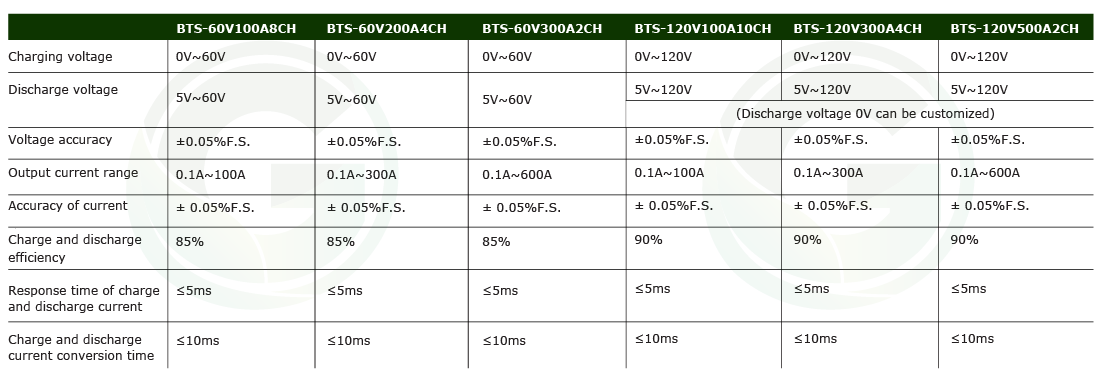

Accuracy of voltage and current is better than 0.05%F.S., automatic selection of current gear. According to the output range of different equipment models, it can be equipped with multi-current gear selection, and automatically select the most suitable current gear according to published parameters. Maximize the accuracy of test data to provide an accurate data basis for battery analysis.

CONDITION SIMULATION FUNCTION

The device simulates any current/power waveform of the battery during the actual driving process such as starting, climbing and braking, providing reliable and comprehensive data to help customers shorten the battery development/validation cycle.

-

- 20MS - Minimum time interval

-

- EXCEL - Support EXCEL import of current/power conditions

-

- 3 MILLIONS - Working condition of article number

FAST CURRENT RESPONSE, AIRTIGHT

Output current quickly reach the set value, support a variety of high-speed dynamic waveform and working condition simulation test.

-

- ≤5ms - Current response time

-

- ≤10ms - Current conversion time

-

- Support a variety of fast dynamic waveform simulation test

EQUIPMENT LINKAGE, A VARIETY OF ENVIRONMENTS CATCH UP

The equipment can be linked with BMS, water cooler, environment box, temperature, pressure and other sensors to form a high-performance detection system; The unified control of BTS software accurately evaluates the electrical performance of battery packs in various extreme environments, and uniformly controls and controls test equipment, making it convenient and simple to operate.

HIGH FEEDBACK EFFICIENCY FACILITATES GREEN PRODUCTION

The energy is transferred to the charging cell for direct utilization and feedback to the power grid. It has no pollution to the power grid, and can effectively reduce the power consumption of the power grid, save power, and greatly reduce the production cost.

-

>0.99 - The power factor

-

90% - Feedback

-

≤3% - Harmonic content

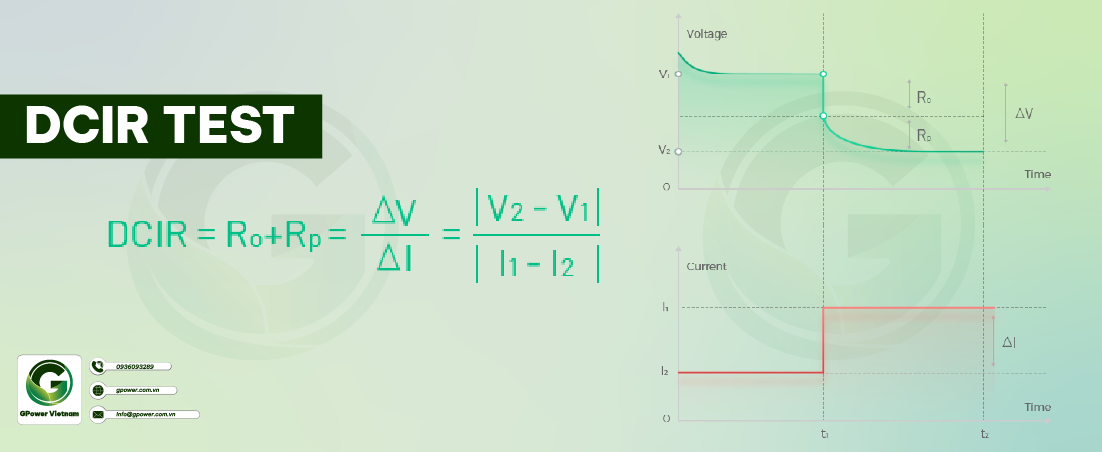

DCIR TEST

The device provides a test method for battery DC internal resistance. It supports setting a value point and automatically obtains the required test result without manual calculation.

BTS SOFTWARE, HUMAN-COMPUTER INTERACTION ONE STEP AHEAD

Battery detection and formation software is the background control system of battery production and testing system, mainly responsible for process step editing, test control, real-time data display, test process data recording and data analysis.

-

- Centralized monitoring of multiple channels on different devices.

-

- A variety of complex work step editing, multiple work step conditions combination judgment.

-

- Generate data reports based on custom templates.

-

- Data recording time:10ms

SAFER TEST

-

- Test safety

-

Comprehensive software and hardware protection measures to prevent misoperation and abnormal conditions, to ensure the safety of testing backconnection protection, wire protection, work step self-inspection, trend protection, etc.

-

-

- Data security

-

When the ac power supply is interrupted, the device automatically records the power supply. After the power supply is restored, the device can resume the test and data is not interrupted. The dual-data technology prevents the loss of test data caused by manual or accidental operations.

-

BATTERY MODULE TESTING EQUIPMENT SERIES

Contact GPower Vietnam for detailed information about the product and accompanying warranty and maintenance services.