A temperature humidity chamber (also known as a climate chamber or environmental chamber) is a device used to create suitable conditions for testing the stability of various materials by simulating conditions such as temperature, humidity, pressure, and light, etc. This equipment is widely used in laboratory settings. To ensure the proper functioning of the equipment, units using the chamber need to carry out the calibration of the temperature humidity chamber.

1. Calibration of temperature humidity chambers

Calibrating a temperature humidity chamber is a measurement and testing activity aimed at assessing the condition, stability, and functionality of the chamber's structure. Calibration work needs to be conducted periodically (once a year) and with care to ensure the smooth operation of the equipment, meeting the needs of the laboratory.

Additionally, it's crucial to carefully choose a reputable calibration organization with the necessary competence, as designated by the government, to obtain certification in accordance with legal requirements.

2. Why calibrate a temperature humidity chamber

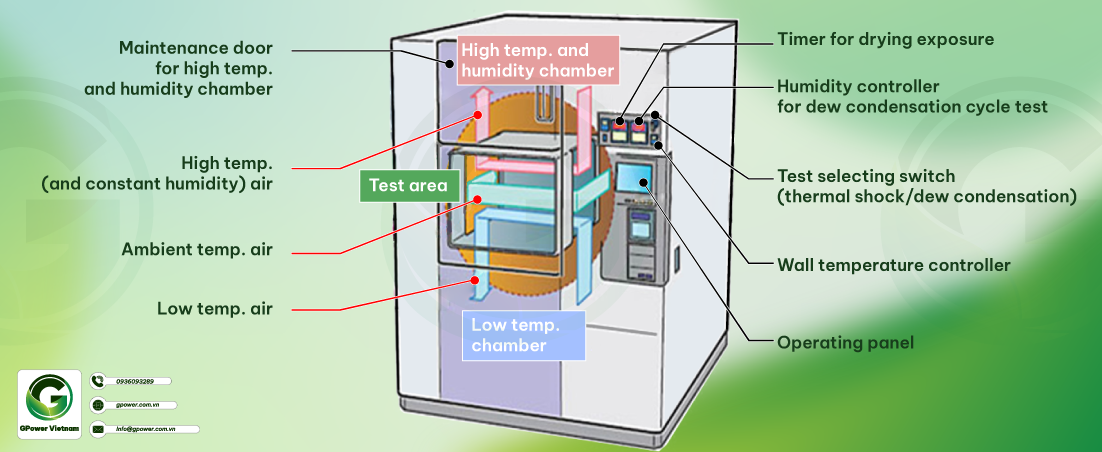

A temperature humidity chamber operates based on two systems: the temperature control system and the humidity control system. These two systems involve numerous components, structures, and subsystems. First and foremost, it is essential to understand the operational principles of these components.

Calibration ensures that the systems receive commands and execute them smoothly, meeting the specified requirements. Additionally, it promptly detects any anomalies in the chamber, enabling timely measures to be taken for rectification, thereby saving effort, time, and the cost of purchasing new equipment.

3. Procedure for calibrating the temperature humidity chamber

Calibration Method: Compare the set/displayed values of humidity and temperature inside the chamber with the standard values measured by the standard equipment. The minimum number of temperature and humidity check points is 03 within the working range of the chamber (or as per customer requirements). Fix one of the two parameters and perform the check from low to high points.

Standard used for Calibration

Calibration Organization will carry out the calibration work according to the following calibration procedure:

Step 1: Calibration preparation

Before conducting the calibration, ensure the following factors:

- - The chamber to be calibrated must be placed in the calibration room for at least 12 hours.

- - Operate the cabinet according to the operating instructions.

- - Environmental conditions: Temperature: (25 ± 5)°C; Humidity: (50 ± 30) %RH

Step 2: External inspection

- - The machine must have complete labels and production serial numbers.

- - The control and display unit is functioning stably.

Step 3: Technical inspection

Check the normal operating status according to the operating instructions.

Step 4: Measurement check

Temperature check:

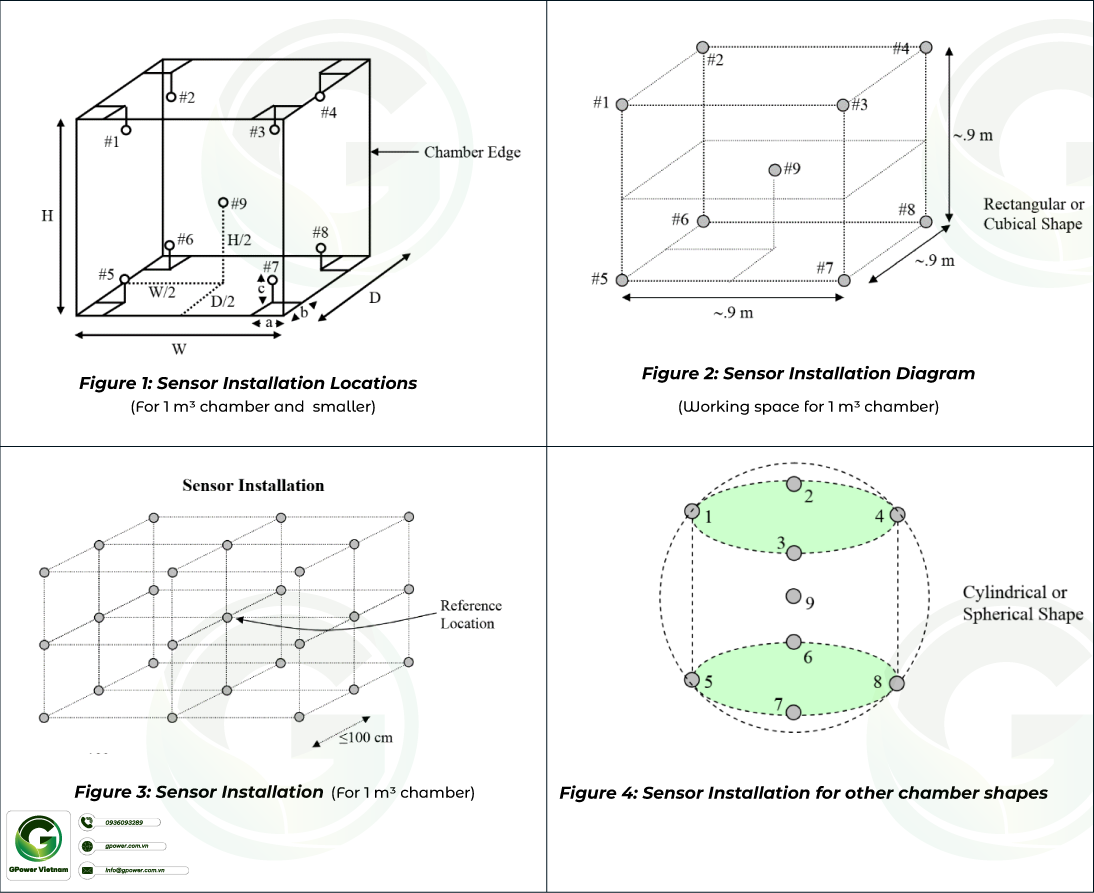

- - Place the temperature sensors according to the layout diagram below, and the sensor positions must avoid the cabinet's ventilation holes.

- - Check the tightness at the sensor locations to prevent outside air from entering the chamber's internal environment.

- - Operate the chamber according to the manufacturer's instructions.

- - Set the chamber's operating mode at the calibration point. When the chamber's value has stabilized for 30 minutes, record the temperature values displayed on the standard device and the set/displayed values of the cabinet at least 3 times in the calibration report.

- - Perform a similar temperature calibration for the remaining calibration points (select 3 temperature points within the device's working range, fix the humidity value). Record the measured results in the calibration report.

Humidity check:

-

- Place the standard humidity sensor in the position of temperature sensor No. 9.

-

- Set the chamber's operating mode at the calibration point, fix the temperature at 25°C. When the chamber's value has stabilized for 30 minutes, record the humidity values displayed on the standard device and the set/displayed values of the chamber at least 3 times.

-

- Perform a humidity calibration similarly for the remaining calibration points (select 3 humidity test points: 20%RH, 50%RH, and 80%RH, fix the temperature at 25°C). Record the measured results in the calibration report.

Step 5: Processing calibration results

Estimation of Measurement Uncertainty

Reference GUM (Guide to the Expression of Uncertainty in Measurement)

General Procedures

- - If the equipment is within the permissible error, remove all expired calibration labels and affix new calibration labels with complete and easily visible information.

- - If the device's error calibrated at all calibration points is less than the permissible error, the device is labeled and a calibration certificate is issued along with the calibration results.

- - If the equipment does not meet the requirements, notify the customer and label it as "Not Compliant."

- - If the equipment meets the requirements only at certain measurement ranges, notify the customer and label it as "Limited."

- - The recommended calibration cycle for the thermometer is 1 year.

References

- Temperature humidity chamber: introduction, structure, applications

- Operating principle of Temperature Humidity Chamber