I. CDD Introduction

CDD file (CANdela Diagnostic Descriptions) is a diagnostic database file defined by Vector, Germany, describing the diagnostic service specification of ECUs and related para-meter format definitions, such as ECU identification, DTC, security levels, sessions, etc. It is mainly used for the development and testing of ECUs.

Usually we need to generate a CDD file based on CDDT and database editing; CDDT, i.e. CDD template, represents the OEM's definition of the vehicle diagnostic specification and does not store specific parameter information.

(Figure 1: CDDT vs CDD content difference, source from Vector website)

The CDD file structure contains ECU information, Diagnostic Trouble Codes, Common Diagnostics/Base, Variants, State, Data Types and Negative Responses. Among them:

ECU Information: Define ECU address information, time parameters, etc.

Diagnostic Trouble Codes: Stores DTC information.

Common Diagnostics/Base Variant: Storage base diagnostic services as well as DID, RID, and failure parameters are defined.

Variants: Used for different phases or versions of the same controller, modified on the base diagnostic information.

States: Define the session mode, the security level and the corresponding switching state of the service.

Data Types: Defines the data type in the parameter.

Negative Responses: Defines the supported negative response codes.

II. Comparison of the characteristics of the CDD and ODX formats

- 1. ODX is an international standard defined by ASAM and ISO, and the data format corresponds to the specification ISO22901-1, while CDD is a Vector private format.

- 2. ODX can package the whole vehicle ECUs into a PDX release, which is easy to manage and suitable for OEM, while CDD corresponds to one file for a single ECU, which is generally used by suppliers for ECU development and testing.

- 3. ODX has the concept of layers, for example: -D stores the description of the whole vehicle ECU diagnostic information, -V is the vehicle topology definition, -F stores the Flash file for flashing, and each layer inherits the data of the previous layer to avoid data redundancy.

(Figure 2: ODX vs CDD)

- 4. ODX is developed by the OEM and is suitable for the whole life cycle (ODX data structure is complex); while CDD is developed for ECU development and is suitable for the development and testing phase (CDD data structure is simple).

- 5. ODX is open protocol, while CDD is private format.

III. Introduction to VisualODX

For the creation of diagnostic database, WINDHILL developed the diagnostic design tool — VisualODX, which can export diagnostic data with one-click by importing diagnostic questionnaires. Currently, it supports ODX/ PDX/ CDD/ DEXT/ ATXML files and mass data processing, which greatly improves work efficiency and accelerates development progress.

(Figure 3: VisualODX Product Families)

CDD export now supports all CDD properties and is available for tools such as CANoe, CANoe.Diva, DaVinci, CANdela Studio by Vector.

| Application Field:

- • OEM diagnostic function development and debugging stage, diagnostic database construction and testing.

- • Production department whole vehicle database creation.

- • After-sales department creates diagnostic database, combined with diagnostic instrument to carry out after-sales inspection.

- • ECU supplier diagnostic function development and testing.

| Software Advantages:

- • Software customisation: semi-customisable software tools to support the expansion of customer-specific functions.

- • Software support for floating version: floating version of the licence, without plugging the hardware dongle can be used, convenient for the use of off-site office team.

- • Project Management: Innovative project configuration interface for easy project engineering management.

- • Standard Excel template: User-friendly and quick to achieve the whole vehicle Excel questionnaire creation.

- • Support multiple ECUs/diagnostic questionnaires import: Support single or multiple Excel import, unlimited number of Excel sheets.

- • Supports exporting ODX/PDX/CDD/DEXT/ATXML files for a single ECU or all ECUs.

- • One-click check: follow the ASAM standard ODX templates, Excel templates combined with double-checking to effectively ensure that the generation of data integrity, accuracy. Support for analysing and locating error messages.

- • One-click conversion: automatically generate ODX/PDX/CDD/DEXT/ATXML files.

| Software Features:

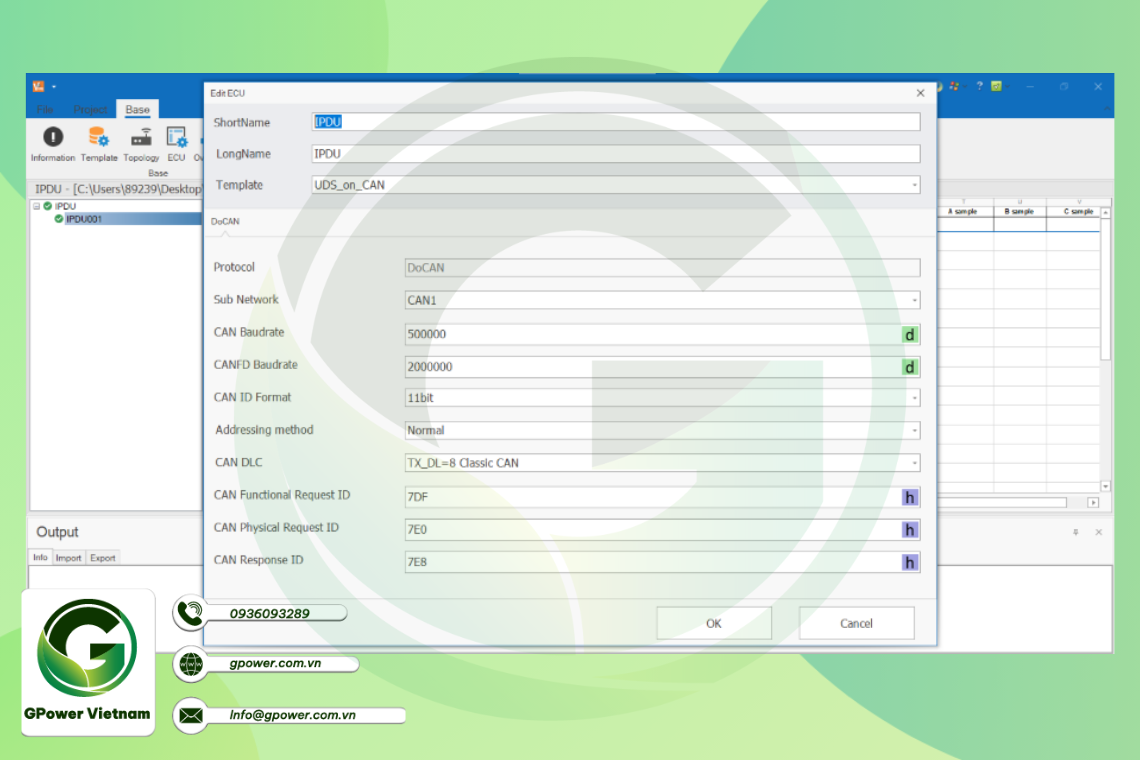

- 1. Add ECU information: Support to add information of multiple ECUs for the project, the number of ECU is not limited.

(Fugure 4: ECU Configuration)

(Fugure 4: ECU Configuration)

- 2. Add ODX Template: Import customised ODX templates for projects.

(Figure 5: ODX Template Import)

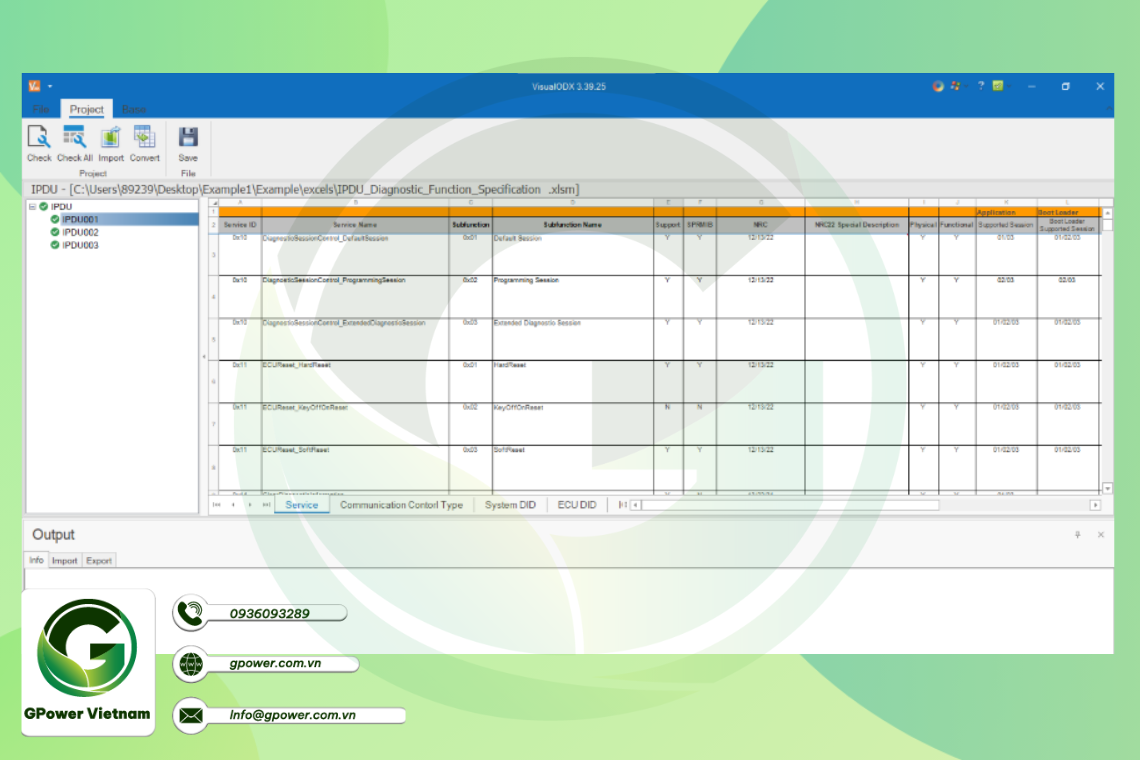

- 3. Import Excel: Click Link to import the Excel sheet. Multiple EVs can be added to the ECU and the number of EVs is unlimited.

Figure 6: Import Excel

- 4. Consistency checking: The errors are displayed in the Output area below, and double click also allows error location.

Figure 7: Consistency Checking

- 5. Convert Function: Convert ODX/ PDX/ CDD/ DEXT/ ATXML files. Not only support for exporting files for individual ECU, but for exporting for multiple or all ECUs in a project.

Figure 8: Convert Function

If there any questions, we are more than happy to support you.