In today's context, technological advancements have imposed rigorous requirements on electric vehicle batteries, a crucial component ensuring the efficient and safe operation of vehicles. This article will provide you with a deeper understanding of the testing methods for electric vehicle batteries and the safety standards they need to meet.

I. Testing methods for Electric Vehicle Batteries

1.1. Battery Safety and Abuse Testing

Testing under harsh environmental conditions and beyond standard operating conditions helps businesses identify product risks and enables a more accurate assessment of primary risks. Impact simulation tests, such as those mimicking a real car accident, are conducted to determine the actual safety performance of the battery when the vehicle compartment is deformed.

1.2. Battery Peformance and Lifecycle Testing

Battery testing encompasses lifecycle tests, environmental cycle tests, and examinations of battery lifespan.

1.3. Battery Environment and Durability Testing

Quality and reliability tests evaluate the impact of external influences on the battery, demonstrating performance in various scenarios through vibration tests, shock tests, electromagnetic compatibility (EMC) tests, thermal cycles, corrosion, salt, dust, and humidity tests.

1.4. Battery Mechanical Testing

For lithium-ion batteries, it is crucial that they withstand compression and tension forces to minimize risks of damage, short circuits, heat, or thermal issues. Testing includes evaluating material properties (tensile, compression, cutting), impact resistance, scratches, abrasion, pressure cycle tests, explosion tests, and leakage tests.

1.5. Battery Material Testing and Chemical Analysis

High-performance materials are increasingly demanded to meet the requirements for high capacity, safety, and long lifespan in lithium-ion batteries. Therefore, testing requirements include State of Charge (SoC), Restriction of Hazardous Substances (RoHS), Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), as well as testing for Volatile Organic Compounds (VOCs), fog, odor, and flammability to ensure that materials meet specific technical specifications.

II. Lithium Battery Standards for Electric Vehicles

In the pursuit of enhancing user experience, electric vehicle manufacturers continually advance technology, and consequently, standards for electric vehicle batteries are constantly improving. Among these, lithium-ion batteries for electric cars are highly esteemed for their outstanding advantages, providing significant benefits for manufacturers and consumers alike.

Electric vehicle batteries play a crucial role in powering all functions of electric vehicles, making them a key consideration for customers choosing eco-friendly transportation. The standards for electric vehicle batteries are evolving to improve travel range, ensure safe operation, and optimize costs.

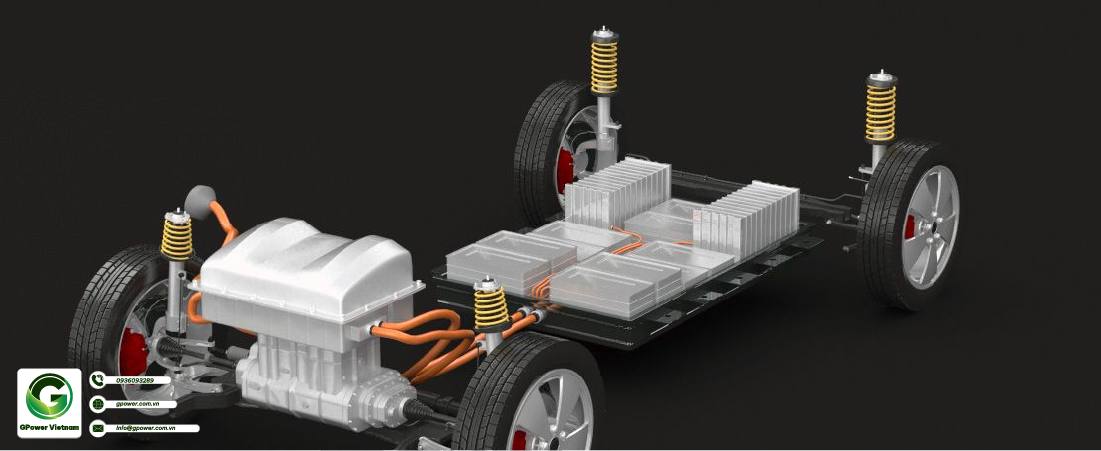

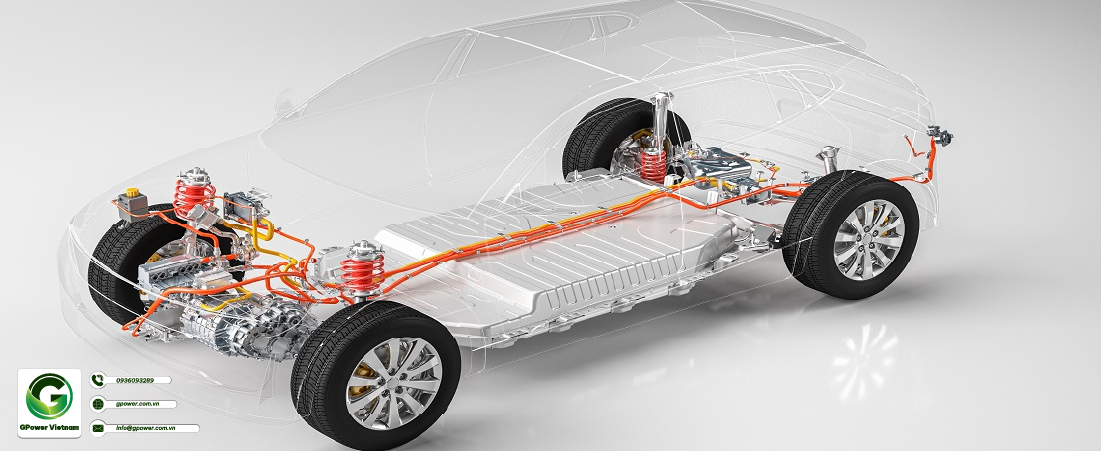

The battery is the component supplying energy for all electric vehicle operations. (Source: Compiled)

2.1. Structure of Lithium-ion Electric Vehicle Batteries

The technology of lithium-ion batteries is widely employed in the electric vehicle manufacturing industry. Thanks to their structure, which consists of multiple compartments containing interconnected battery cells, including two positive and negative electrodes, and a ceramic-coated separator to prevent leakage, Li-ion batteries allow for multiple charge cycles and ensure excellent safety against explosions.

2.1.1. Battery Casing for Electric Vehicles

The lithium-ion battery casing exhibits excellent impact resistance, remaining undistorted even when subjected to strong external forces during collisions. The internal battery block contains ceramic-coated separator strips, replacing conventional permeable membranes, thereby enhancing battery lifespan. Additionally, lithium batteries demonstrate efficient heat dissipation and adaptability to challenging conditions.

2.1.2. Battery Module Separation Component for Electric Vehicles

The separation component of lithium-ion electric vehicle batteries typically consists of a permeable membrane made of PE or PP plastic, positioned between the positive and negative electrodes. Its primary function is to maintain a distance between the two electrodes to limit the occurrence of short circuits. Charged ion particles can also move through the permeable membrane, completing the circuit when an electric current flows through the electrochemical cell.

The permeable membrane is divided into two types, suitable for either dry or wet batteries. Currently, membranes designed for wet batteries are more widely used due to their simpler operational processes and evenly distributed permeable hole sizes, optimizing efficiency.

The electric vehicle battery is constructed with multiple layers to enhance durability and ensure safety during use. (Source: Compiled)

2.2. Technologies Ensuring Safety for Electric Vehicle Batteries

During usage, a short circuit can lead to power loss, directly affecting the vehicle's operation. To ensure continuous operation, manufacturers have equipped electric vehicle batteries with various safety technologies, including:

-

- Component Collision Control Technology

Electric vehicle batteries have direct connections to the engine and other electrical components. Therefore, in case of a system failure, collisions and pin failure are likely to occur. To minimize external impacts, manufacturers incorporate safety features to protect the battery effectively.

-

- Active Protection Technology

The Battery Management System (BMS) monitors the charging status, battery cells, and automatically adjusts the entire battery operation to prevent incidents. If abnormalities are detected, the relay component will automatically adjust (turn on/off) the power supply to ensure safety, preventing pin connector ignition.

-

- Circuit Breaker with Fuse

The fuse acts to cut off the electric current when a short circuit is detected within the battery, ensuring safe operation.

-

- Electric Shock Prevention Mechanism During Charging

To protect the battery during outdoor charging in heavy rain, manufacturers have designed it to prevent water from flowing into the charging port. Simultaneously, the vehicle is designed with openings to vent moisture and prevent electric shock.

When users plug the charging cable into the vehicle's charging socket, the locking lever will close, creating a sealed space for the charging current to pass through continuously. The charging process only stops when the plug is disconnected, preventing risks arising from the contact points of the connector.

Electric vehicle batteries are equipped with safety technologies to limit incidents when the vehicle is impacted from the outside. (Source: Compiled)

2.3. Standard Safety Tests for Electric Vehicle Batteries

Before being applied to manufacturing, electric vehicle batteries must undergo numerous safety tests and adhere to electric vehicle battery precautions to limit incidents and ensure the most stable operation. Specific safety tests include:

-

- Collision Safety: The vehicle undergoes tests for impacts from various directions to assess the battery's impact resistance.

-

- Waterproofing: The vehicle is operated in flooded areas and heavy rain to test the battery's waterproofing ability.

-

- Water Immersion: The vehicle is immersed in saltwater for an extended period to determine the battery's wet resistance duration.

-

- Fire Testing: The battery undergoes direct fire testing to assess its heat resistance.

2.4. UL 2580 Electric Vehicle Battery Safety Certification

UL - Underwriters Laboratories is an organization specialized in testing and evaluating the quality of various industrial products before they are introduced to the market. Among them, UL 2580 is the highest safety certification for electric vehicle batteries.

Achieving UL 2580 safety certification is a mandatory requirement for lithium-ion battery suppliers. The certification is conducted by reputable international organizations such as Underwriters Laboratories (UL).

Tests on battery limits and battery module constraints will be performed in test chambers to determine impact resistance under adverse conditions and the safety of battery use.

2.4.1. High Current Battery Short Circuit Test

This test is performed on a fully charged battery sample. The short circuit test is conducted by connecting the positive and negative terminals of the battery and applying a load greater than or equal to 20 mΩ.

The test is repeated at a load with a maximum current of 15% of the previous short circuit protection circuit's efficiency. Samples will reach thermal equilibrium when the terminals are connected. Throughout the evaluation process, the tested battery samples may need to undergo a fire test to detect flammable gases inside to ensure no combustion or explosion occurs.

2.4.2. Battery Crush Test

The battery will be tested for high-intensity force to ensure safety for the driver and the vehicle in the event of a collision. In the test chamber, the battery will be sequentially crushed by three types of rolling pins on the prepared surface:

- - Method 1: Three perpendicular contact axes are arranged, and the battery is crushed from three different directions.

- - Method 2: Using EESA with 2 symmetrical perpendicular axes and contacting the battery in two different directions.

- - Method 3: Using a DUT protective frame during crushing.

Additionally, experts will use an electric spark to detect the concentration of flammable gas inside the battery. If the tested samples do not exhibit combustion, explosion, or release toxic gas, they will be UL 2580 certified.

Electric vehicle batteries must undergo numerous safety tests before being installed in cars (Source: Compiled)

2.4.3. Vertical Battery Crushing Test

According to the UL 2580 battery test, standard crushing tools must be cylindrical or semi-spherical. During the test, the battery will be tightly clamped and subjected to a squeezing force of 2500 (17.2Mpa). After completing the test, a battery that does not emit smoke, burn, or explode will be UL 2580 certified.

2.4.4. Horizontal Battery Crushing Test

The UL 2580 test crushes the battery horizontally to evaluate its robustness. Crushing pressure is generated from the hydraulic head of the piston and applied until the hydraulic pressure head reaches 17.2 Mpa, with a total force of approximately 13KN used. Additionally, during the crushing process, the battery must be parallel to the surface of the crushing device to test its load-bearing capacity.

2.4.5. Seawater Immersion Test Equipment

The seawater immersion test is performed to test the battery's discharge capability and electric shock prevention for users when the vehicle is forced to move in flooded conditions or when there is an accident where the vehicle falls into the water.

In the testing room, the vehicle battery will be completely immersed in saltwater for 1 hour. The result shows that a 12V battery can discharge energy for up to 1 hour. Accordingly, rapid energy release time will help prevent the car doors from closing tightly, making it easy for occupants to escape when the vehicle falls into the water. However, experts believe that electric shock or fire incidents may occur if the battery is submerged for too long.

2.4.6. Heat Dissipation Test

When a lithium-ion battery malfunctions or overheats, it can generate heat and electric sparks. The heat can cause the battery to catch fire, and the rapidly released gas can damage the battery casing. The UL 2580 battery test aims to enhance overall awareness of the heat dissipation risk.

The heat dissipation test chamber includes an external heater used to heat the cells to dissipate heat, a nichrome wire used for heat conduction, and connected to the cells using Kapton tape. Continuous voltage is applied to the van until the battery enters the heat dissipation state. During the test, the spring coil is usually supplied with power ranging from 30W to 50W.

Electric vehicle batteries must meet the UL 2580 standard before being released from the factory (Source: Compiled)

The standards for lithium-ion electric vehicle batteries help increase the range of travel and improve the adaptability of the vehicle to adverse operating conditions. To ensure the battery system can operate in optimal conditions, users should use the correct genuine charger to ensure compatibility with the vehicle. Additionally, to protect themselves and extend the battery life, users should not frequently use the vehicle in conditions that pose significant risks.

References