Horizontal Battery Crush Nail Penetration Test Machine Main Feature

- - Dual Hydraulic Cylinder drive, Energy Saving up to 30%. (Patented Technology)

- - High Precision Process, Electro-hydraulic Servo Drive.

- - Humanized design operation, the easier specimen install process, operator process without bending down, avoid injury.

- - Dual Explosion-proof Safety Protection device.

- - Space Saving, crush and penetration 2 in 1.

Standard

- - UL 2580

- - ECE R100

Relevant standards requirement

- Test object: Battery storage pack or system.

- Crush according to the following conditions

- - Crush plate: half cylinder with radius 75 mm, length of the plate should be larger than the crushed battery size but shorter than 1 m;

- - Crush Direction: X and Y direction (car driving direction called X-axis, another horizontal direction perpendicular to the car driving direction called Y-axis). To ensure the safety of test operations, tests can be performed on two test objects separately.

- - Crush level: Stop the crush when the crushing force reached 100 KN or the crush deformed by 30% of the total size of the crush direction of the battery pack, remain for 10 mins.

- After testing, observe for 1 h under the testing temperature.

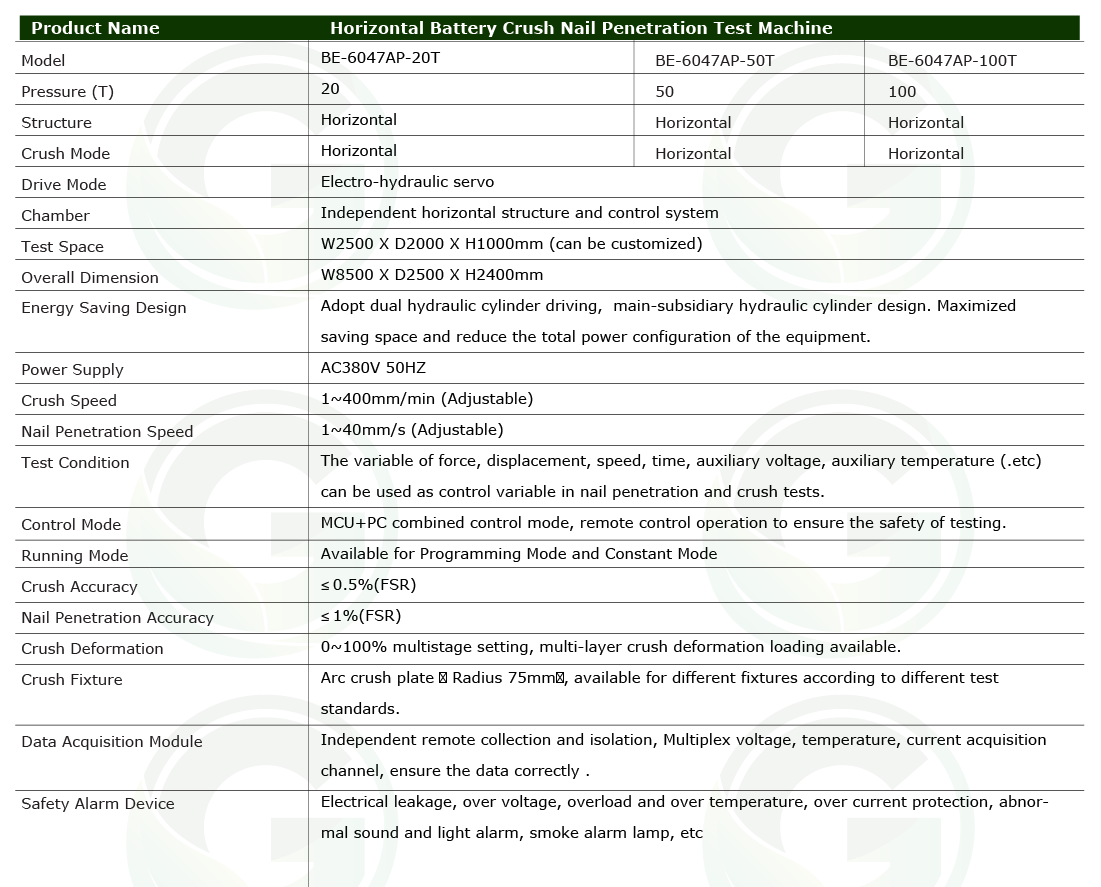

Battery Crush Nail Penetration Tester Technical Parameters

|

|

||

|---|---|---|

Horizontal Battery Crush Nail Penetration Test Machine Safety device

1. Flame resistance and explosion-proof design for the test area

The test area is composed of all high-temperature resistant and flame-proof components (no plastic piping, wires, rubber gaskets, seals, lubricants, oils, etc.), which prevents damage to the equipment due to battery combustion and explosion.

2. Rust-proof and anti-corrosion design for the test area

Test area steel frame surface spraying, guide rod hard chrome coating, with high strength, waterproof, rust-proof and anti-corrosion design, to avoid the battery test combustion, explosion when using firewater to extinguish the equipment produced by the adverse results.

3. Emergency stop button

Emergency stop switch, an emergency stop all tests, and at the same time cut off the power supply to avoid short circuit hazards.

4. Crush limit protection device

The main cylinder and auxiliary cylinder are installed with upper limit and lower limit protection devices respectively.

5. Equipment own overpressure protection

The oil source system is installed with a system pressure protection module, when the pressure exceeds the set value, the oil circuit system will automatically release pressure to protect the oil circuit and the host. Also installed with motor overcurrent protection, squeeze pressure upper limit protection, system overload protection, phase sequence protection, etc.

6. Other aspects of safety design

The equipment has electrical safety by the national standard requirements, which can effectively prevent and eliminate the possible electric shock hazards of operation and maintenance personnel. In normal operation, in addition to the circuit part of the equipment, the shell of the equipment, metal parts in the test chamber, etc. will not appear electrically charged. In the event of an accident, such as fire, leakage, short circuit, etc., the equipment can automatically cut off the external input power, so that any part of the internal equipment is not charged.

7. Waterproofing of the test area

The ground of the equipment test area digs a drainage ditch, and after the firewater spray, the water is discharged to the outside through the drainage ditch to prevent the equipment from accumulating water and rusting. All pipes have waterproof joints to ensure the safety of the equipment circuit and oil circuit.

One set each of extrusion needling mainframe, computer cabinet, control software, voltage and current temperature collection system, extrusion fixture, camera monitoring system, and computer, etc.