Labtone EV series of electromagnetic vibration testing system simulate the vibration environment under the laboratory condition, and test the impact strength as well as reliability of various vibration test applications. In the laboratory, with the aid of vibration testing system, simulations of reproduction of sinusoidal, random, resonant search and dwell, classical shock and road models, etc. can be achieved. It is essential for product quality assurance, new product research and development.

Labtone EV series of electromagnetic vibration testing system is specially designed to meet the need for long time operation. Vertical and horizontal vibrations can be achieved by the installation of vibration resistant base. The standard platform is equipped with high efficiency airbag shock isolation device, so that the vibration transmitted to the building can be minimized. There is no need for additional foundation in most of the cases.

A complete set of vibration testing system is composed of shaker, power amplifier and vibration measuring control system, in accordance with the relevant national and international standards (such as: MIL-STD, DIN, ISO, ASTM, IEC, ISTA, GB, GJB, JIS, BS, etc.) to provide technical support for establishing product quality inspection.

1. Main Features

- - Rugged suspension system and linear motion guiding, strong carrying capacity, good guiding functions, high stability

- - Load center airbag has high static stiffness and low dynamic stiffness, strong carrying capacity, perfect performance on amplitude variation

- - High efficiency D class power switching, 3-sigma peak current, provide finest power consumption and minimize harmonic distortion

- - Quick self-diagnosis with safety interlock, high safety reliability

- - Airbag shock isolation device for vibration platform without the need of additional foundation, perfect reproduction of vibrational wave and reduce vibration transmittance

- - Provide horizontal and vertical expansion platform for different application

- Simple controller operation

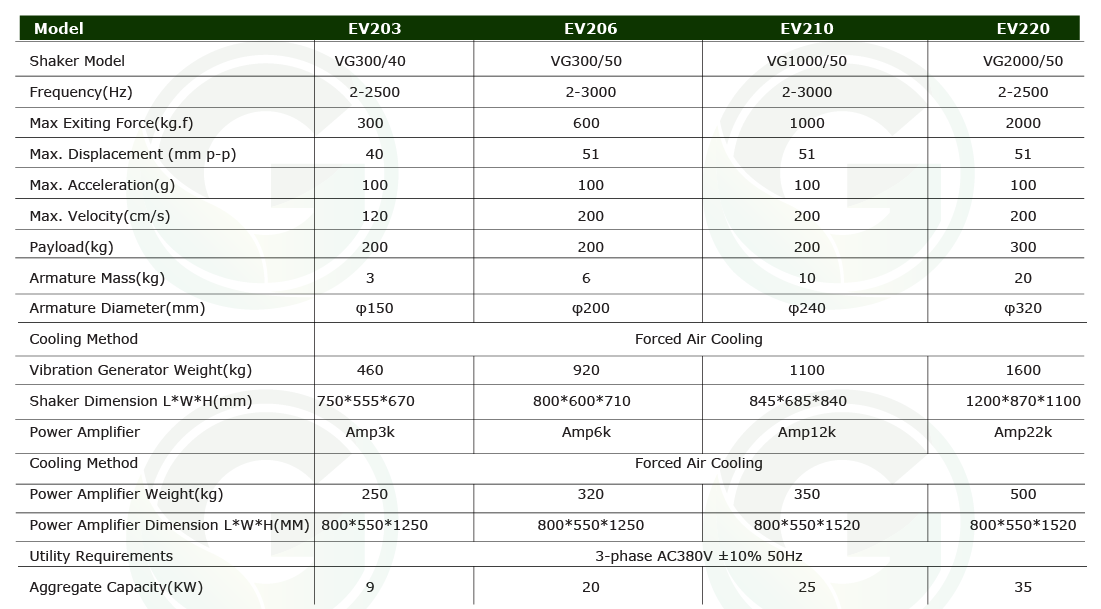

2. Technical Specifications

3. Applications of Dynamic Shakers

- - Automotive parts and systems – qualification testing

- - Electronic assembly, computer equipment testing

- - Avionics and military hardware testing

- - Satellite component testing

- - Product and package testing

- - General stress screening

4. Performance of Dynamic Shaker

The maximum acceleration level of an electromagnetic shaker is determined by the maximum current and the loading condition. At low frequency, displacement of moving part is limited such that the acceleration will not reach high level. The resonance frequency of the moving element is designed to be higher than the upper limit of the frequency range of the shaker.

5. Selection of Shaker Model

To choose a suitable vibration test system, the most important thing is to know the exciting force required to perform the vibration test. To evaluate and calculate the exciting force, the following data should be specified:

- - Frequency (frequency range)

- - Maximum Acceleration

- - Maximum Displacement

- - Maximum Velocity

- - Specimen Mass and Fixation

The specimen fixation is selected based on the upper limit of test frequency and specimen size, either vertical expansion platform or horizontal slip table. Specimen mass is needed to evaluate the required exciting force for vibration test.

6. Labtone service

6.1. Pre-Sales Service

- 1) Technical consultation: test method, laboratory planning and suggestion.

- 2) Equipment selection: selection scheme, FAQ.

- 3) Product testing scheme.

- 4) Customer communication and progress report.

6.2. After-Sales Service

- 1) Technical training: operation of equipment, daily maintenance, common fault diagnosis and troubleshooting.

- 2) Scheduled on-site service: Detection of problem as soon as possible in order to eliminate equipment and anthropogenic hazards. This is to ensure long term and stable equipment operation as well as delivery of latest technical information.

- 3) Technical support: special paid services are provided according to customer’s needs.