1. Standards

DGBell BCW-400 Condensation water test chamber meets the automotive condensate water test standards of GM, FORD, VOLVO, etc. Completes the condensate water test in accordance with the standards of ISO 6270-2, VCS1027, 33759.

2. Scope of Application

The main application scope of the condensation water test chamber: Testing of materials such as paints, metal parts, spraying, automotive exterior parts, anodizing, etc. - for temperature and humidity resistance.

3. Atmospheric Reference Diagram For Condensation Test

During the operation of the equipment, the depth of the water inside the equipment should be at least 10mm, and this water depth should be maintained throughout the operation.

Note: It is recommended to use distilled water and water that has been ion-depleted to prevent instrument calcification.

4. Test Sample

At any time, the coatings that are exposed must not affect each other.

5. Arrangement of Test Samples

The arrangement angle of the test specimens within the test chamber should be greater than or equal to 60 degrees. In this case, to ensure adequate heat dissipation, they cannot be placed closely together.

Minimum observation interval: Distance from the wall should be no less than 100mm.

The distance from the bottom edge of the test sample to the water surface should be no less than 200mm.

The distance between adjacent test samples should be no less than 20mm.

Take preventive measures to ensure that no condensation water from the walls and ceilings of the aging test chamber drips onto the test samples, including those of other items.

When the specified coating damage occurs or when the specified duration or cycle value is reached, the test will be ended.

6. Performance

7. Structure

8. Air Conditioning Device Remark

- (1) Regulation and Control: Forced convection balanced temperature and humidity control mode;

- (2) Heating: Nickel-chromium wire heater, controlled by SSR;

- (3) Cooling Mode: Natural cooling

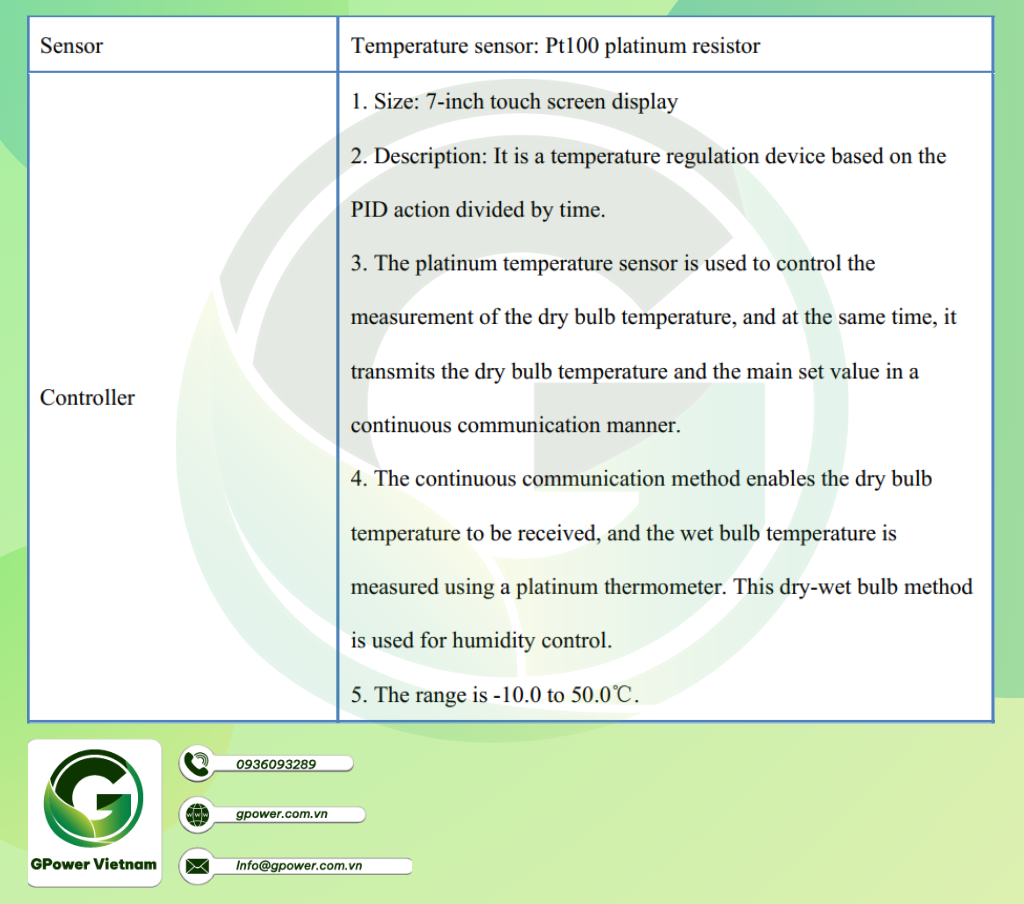

9. Control System

10. Safety Protection Function

- 1) All the electrical components, including fuses, protection switches, controllers and related regulating devices, are integrated in the electrical cabinet.

- 2) Phase loss and reverse phase protection of the power supply

- 3) Over-temperature protection

- 4) Over-temperature protection of the heating zone

11. Equipment Working Conditions Remark

- 1) Ambient temperature: +5℃ to +35℃

- 2) Relative humidity: ≤80% RH

- 3) Power Requirements:

- 4) Voltage: AC 220 ± 10% V, Frequency: 50 ± 0.5Hz;

- 5) Installation power: 3.5KW

- 6) Maximum current: 20A;

Contact GPower Vietnam for detailed advice on equipment, solutions and quotes.